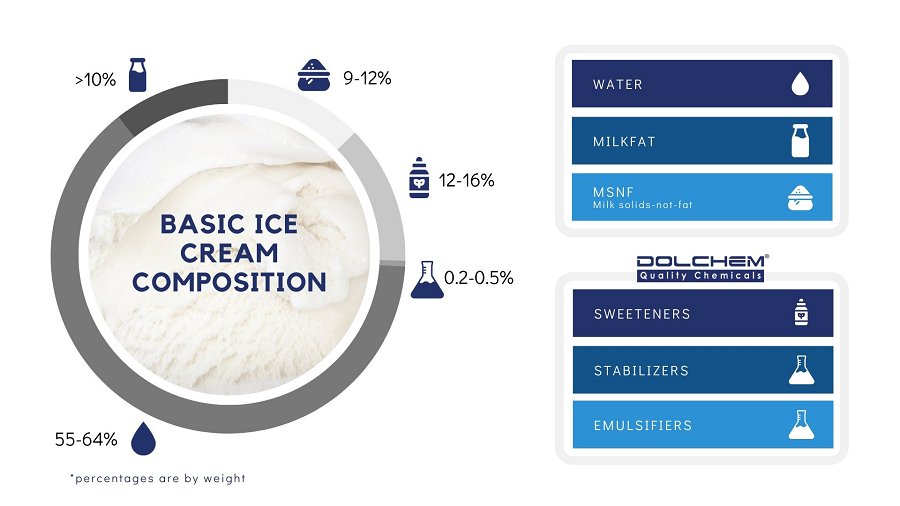

Classic ice cream composition is quite simple and does not require a lot of ingredients. In general, it comes down to the following list (percentage by weight):

- Milkfat, between 10% and 16% fat content

- 9 to 12% milk solids-not-fat (MSNF)

- 12 to 16% sweeteners

- 0.2 to 0.5% stabilizers and emulsifiers

- 55% to 64% water which comes from the milk or other ingredients

While this list is good in theory or for the starters, the reality usually implies a large variety of flavors, product features, and guidance. Every country has its regulations for ice cream. In Canada, for example, two types are present — Ice cream mix and Ice cream. Each has a different set of regulations. In addition to the ingredients above, manufacturers are allowed to use flavoring preparation (such as fruits, nuts, etc.), coloring and pH adjusting agents, sequestering agents.

Stabilizers and emulsifiers

Stabilizers and emulsifiers are essential to produce ice cream on an industrial scale. Despite their smallest share in the composition, they can affect the ice cream texture greatly. These agents are in charge of making ice cream silky, creamy, smooth, and thick.

The most common emulsifiers used at the modern factories are mono- and di-glycerides (DMG). They are highly helpful in making ice cream smoother and thicker with a better mouthfeel and enhanced meltdown capabilities. This is possible because DMG reshapes the fat structure preventing it from separating. It also controls the air distribution in the mix.

The main purpose of adding stabilizers to ice cream is to prevent the product shrinkage and moisture migration to the package by stabilizing air bubbles. Besides, stabilizers help to hold the flavoring particles in the mix and ensure good flavor release. Excellent ice cream stabilizers are Microcrystalline cellulose (CMC) and Xanthan gum (XT). Taking the function of bodying and texturizing agents, these two food additives are usually used in combination and are responsible for adding viscosity to the formulation mix.

Another frequently used additive, Propylene Glycol Mono Fatty Acid Esters (PGE), is permitted for use in Canada as both emulsifier and stabilizer in ice cream. Separately or in combination with other agents PGE helps to control ice crystal size, to melting properties, fat emulsification, and mouthfeel.

Sweeteners

Sweeteners also have some impact on the ice cream viscosity and melting point, not to mention the overall taste perception. Most manufacturers tend to replace sucrose (or simply, sugar) with another less calorie-rich additives like Dextrose or Glucose. Enhancing the ice cream taste, they also make it softer, less frozen, and thus easier to scoop. It is also important for the production process that adding sweeteners affect the freezing point making it lower.

pH Adjusting Agents

pH Adjusting Agents might be needed since the slightest alteration of pH changes the flavor, consistency, and shelf-life of a product. Citric Acid and Sodium Citrate, or a combination of these two – Trisodium Citrate, can be used in ice cream mixes to achieve the desired level of pH.

Sequestrants

Generally known as sequestrants, Sodium Acid Pyrophosphate (SAPP) and Sodium Hexametaphosphate (SHMP) can be applied for ice cream mix productions under Good Manufacturing Practice. While they are not strictly necessary in ice cream formulation, they allow controlling product taste, volume, and color.

Formulating your best ice cream or following your country’s food requirements might be not as challenging as finding a reliable food additives provider that is able to supply you with all the ingredients at once. Whether you are sure what additives you need or not, it is easier to choose the right ones with an experienced raw materials provider – DOLCHEM®. Get in touch for more details and further discussion: